Recently I was doing some woodworking and wanted to try fuming a small test piece of oak with ammonia. The fuming process darkens the wood and gives it a nice aged, gray look. To speed the process up, I decided to heat my ammonia solution to increase the rate of evaporation. With nothing else on hand and with a desire to do something fairly ridiculous, I decided to use a vacuum tube as an immersion heater in a closed-loop PID heating setup for my ammonia fumer.

Disclaimer: This is a sub-optimal solution to this problem, don’t try this at home, ammonia vapor is poisonous, etc…

I tried using an aquarium heater to heat some ammonia first, but the heater I had lying around was dead. Without a good supply of low-value resistors on hand, the only heating element I could find around the house was the heating filament in a half-dead 6v6 vacuum tube. The tube I chose was slightly cracked, so I applied some RTV in an attempt to seal the crack.

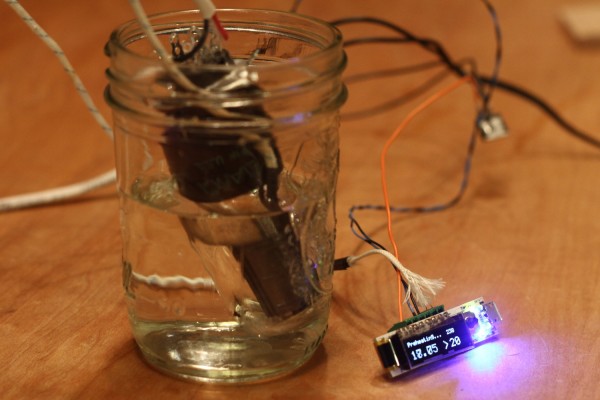

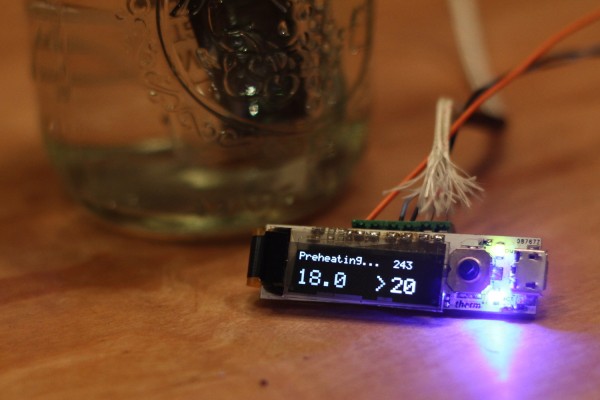

Next I attached the heater of the tube (which still worked) to a 6v power supply and FET driver board I designed, which was in turn hooked up to a PID controller (yet another project I’ve been working on recently, more details to come soon).

I suspended the vacuum tube and thermocouple in the ammonia solution and placed the whole setup in a large mason jar, which I sealed off to prevent fumes from leaking out. Over the course of about 15 minutes I was able to get the solution to a temperature of 30C, and the ammonia produced a nice noxious vapor (read: don’t breath ammonia vapor! It’s poisonous!).

Over a couple of hours some water started leaking in through the crack in the tube, so my RTV must not have completely sealed the crack. Nevertheless, I let the setup run overnight and it kept on working just fine.

The next day I had a well-fumed piece of ammonia, which you can see on the right in the photo above. The fuming gives it that nice old barnwood look, which warms up to a nice amber color after some boiled linseed oil is rubbed into it. Another cool thing about fuming is that it penetrates deep into the wood—I cut my small test piece in half, and the wood maintained the same aged look all the way through. In the Spring months I plan on fuming an entire desktop (outdoors, for safety), but hopefully I’ll have a better solution than a vacuum tube for heating my ammonia by then!

Care to post an after shot of the ammonianated wood? I’m curious to see how it turns out.

Cool project, btw, and full marks for the resourcefulness. 🙂

Thanks! Check out the last photo on the right hand side, it shows a before/after of a test piece. That piece was only fumed for 12 or so hours, fuming for longer periods of time distresses the wood even more.